What’s the biggest cost in agriculture? Labor.

Lars Petter Blikom explores the impact of manual labour on the overall operating costs in the orchard.

The most urgent problem to tackle in fruit, berries, and vegetable farming, is the reliance on manual labor. Over the past hundred years, mechanization of farming has enabled broadacre farmers to farm ever-increasing land areas with bigger machinery – not more hands.

Unfortunately, this development has mostly not spilled over into fruit, berries, and vegetables, where typically weeding, harvesting, and other jobs in the fields are still manual processes.

For my own farm in Norway, I believe phasing out manual labor over the next 5-10 years will be a make-or-break for our business. The main reason for this is twofold: First, it costs too much. Second, it’s too hard to comply with regulations.

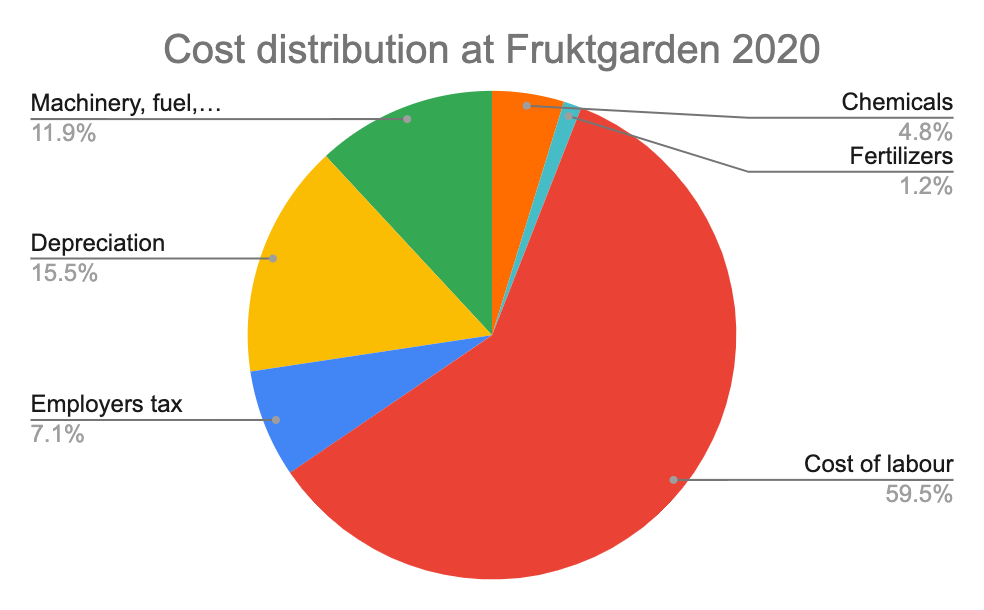

Again I use my own farm as a calculation example. Remember, we grow strawberries, raspberries, apples, plums, and pears over 50 hectares. 60% of total costs in 2020 were salaries. These salaries also generate an “employer´s tax” – this is our Government punishing us for giving somebody a job… for which they can pay more taxes. This tax adds about 7%, taking our total labor costs to 67%. In other words, in the search for cost reduction opportunities, look no further, it has to happen in this cost item.

There is no denying that seasonal labor work in agriculture hasn’t been an easy way of making a living throughout history. But politicians and the public are typically hypocritical about the issue. They want all employee groups to make more money and have more benefits, but when they visit the grocery store, they want the food to be cheap.

Since this is a sensitive topic, let me be very clear: I want only the best for every worker in the industry and in particular our own seasonal workers.

However, when the cost of producing exceeds the value of the produce, the system breaks. Nobody gets a job. Nobody gets food.

I know that Norway is not representative of salaries and worker regulation across the world, but I think Norway´s general wealth just allows us to move along this trend faster. The rest of the world will follow in due course. And if I am right, fellow farmers in other countries should prepare to offer single bedrooms with shower and TV for all seasonal workers, no more than 8 hours of work per day (with very small room for exceptions), no flexibility to shift around work hours: If it rains and you can’t harvest, you pay salaries anyway. If your strawberries ripen a week later than you planned, you pay salaries anyway. If you hire somebody who proves unable to do the job, you pay salaries anyway.

The fundamental problem is simple: The value a seasonal worker produces in 8 hours is not enough to pay for a single bedroom with a shower and TV. This is a fact, regardless of ethical and moral values, and political discussions about the value of people.

I see only one solution in the short to medium term in Norway, probably the medium to long term in the rest of the world: Phase out manual labor.

Coronavirus has forced farmers across the world to rethink everything they do. I am sure they have come across ideas that they just wouldn’t have thought of in a normal year. At my farm we have. We have switched to mechanical pruning and saved 2000 hours of manual work. It’s hardly new technology – fellow fruit farmers elsewhere will think this switch should have been done decades ago. Many tasks can be at least partially switched to machinery with a little bit of external motivation. However, there will still be many tasks that still require manual labor.

Set aside a few hours to google farming robots. It’s really encouraging. They will spray and fertilize only in the necessary spots, they will prune, thin, and harvest.

I just don’t want to own a robot. I really don’t. Because I know that in agriculture, everything breaks all the time.

Farmers are awesome handymen. In general, they fix everything themselves. Mechanical and electrical failures? No problem. Hydraulics? No problem. Pumps and compressors? No problem. But a malfunctioning control system of a robot?

Besides, how do you tell the robot where to go and what to do? And how do you know what it actually did after you think you told it to do something? I am sure it didn’t go to the pub for a pint, but did it spray correctly? Applied the right dosage at the right place?

There are many great initiatives to develop robots for agriculture, but as before it will be up to the farmers to deploy them in the field. And to do that, there needs to be processed in a place that gives confidence in the reliable execution of jobs in the field. There is very little room for mistakes because as discussed before, the mistakes can’t be corrected until next year.

Farmers must therefore prepare. And the best way to prepare is to start developing the systems and models that connect farmers to robots in the future. And that preparing starts with reinventing how you gather, organize and use your data.

This is part five in a seven-part series on a farmer’s journey to precision agriculture.

Part 1: Precision agriculture isn’t what they say it is

Part 2: What problems will precision agriculture solve

Part 3: Reinvent how you gather, organize and use your data

Part 4: Why measuring return on investment per field is still a challenge

Part 6: How to get your orchard future ready? Start automating documentation

Part 7: How variable zoning can lead to more precision in agriculture